Something else about Twins, PLM and MES

The year was 1988. Ronald Reagan was President. The US was about to win the Cold War. Windows 3.1 had not been released yet, CAD systems were in their infancy, and PLM as a term did not even exist. In 2022 everything is …different.

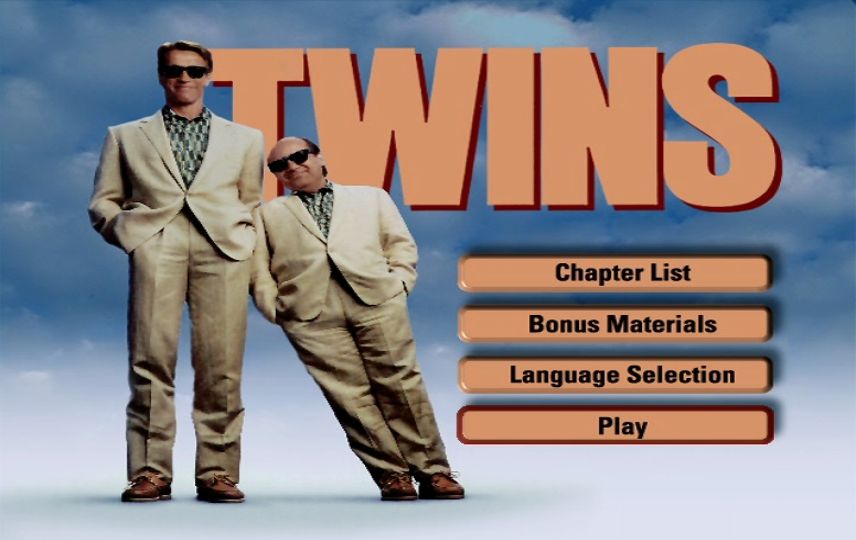

In the 1988 comedy called “Twins“, scientists manipulated genes of several outstanding gentlemen to create an embryo with perfect DNA, and then used it on a female volunteer. Unexpectedly, instead of a single perfect child, the mother gave birth to a pair: one very much a “perfect” child, and the other one highly “imperfect”.

Vincent Benedict, the “imperfect” child played by Danny DeVito, is a chubby, impulsive, criminally inclined character with analytical abilities of a chimpanzee, who randomly crosses all kinds of bad people who in turn want to “whack” him.

His “perfect” twin Julius Benedict, played by Arnold Schwarzenegger, is literally a bodybuilding champion, highly logical, but totally innocent in many earthly matters. Something tells me that without assistance his future doesn’t seem entirely bright either.

The brothers’ intellectual abilities and mental features look like they were literally torn apart from a single solid character. They can sense each other’s thoughts and feelings, and their body movements are identical in similar circumstances. In the movie’s happy end they succeed in business and life when they start working together – as one.

From the 2022 perspective, the “perfect child” project’s PLM process was fine – because each brother came out as a homo sapiens in terms of hardware and software. It was on the womb’s shop floor that things went astray: the assembly line created two units instead of one. The same software was installed into these two units, using two different configurations. All things being equal, I am going to blame the mother’s grossly mismanaged manufacturing execution system.

It is a funny coincidence that bearing a child and assembling an aircraft take considerable time. A human child is definitely more comparable to an aircraft than to a car or to consumer goods – every aircraft is unique and very expensive. The question is whether one can use an MES designed for consumer goods for producing an aircraft? Probably so – but with some serious customization. However, an MES created ground-up for complex and/or highly regulated products might be a better choice than a generic system.

There are a number of MES vendors on the market of 2022. In my view, only iBASEt Solumina family of applications seems to offer that clean ground-up vision and out of the box functionality for that particular niche. That’s why with the Senticore focus on aerospace, defense, and other complex products-oriented customers, we chose to become an iBASEt business partner. Our immediate agenda in this partnership is to assist iBASEt customers with their migrations, infrastructure needs, DevSecOps and 3rd party integrations, especially with PLM systems.

On a separate note, MES systems are often homegrown for smaller companies, and gradually get more and more complicated. Then, a major aerospace OEM may acquire these various locally owned aircraft parts and custom interior shops that have been operating for 20 years, with their own software and processes.

The perfect pair of systems is PLM and MES, when they work together seamlessly. An OEM’s centralized PLM system can serve all sites – because it deals with a virtual world; MES systems end up having unique attributes per site. Some things are purchased and built differently, depending on the needs of the business. This creates process variations in the software. Since the different locations are using different systems that are not compatible with each other, the Materials and Planning organization cannot view the purchasing of the whole company from a bird’s eye view to make better buying decisions.

Thus – migrations of all these MES to a single system becomes imperative. The problem is, one cannot just turn older MES systems off without bringing much of the business to a halt. Things get complicated quickly…

The year is 2022. While I will refrain from advising about politics, wars or making babies, Team Senticore can confidently help you with all PLM and MES needs, so your hardware products will be produced in the right numbers and with the right features.

P.S. Senticore is a sponsor at the iBASEt 2022 conference in Orlando. We encourage you to attend, and if you do, I will be happy to meet you there to discuss how to make your imperfect PLM/MES babies perfect again.